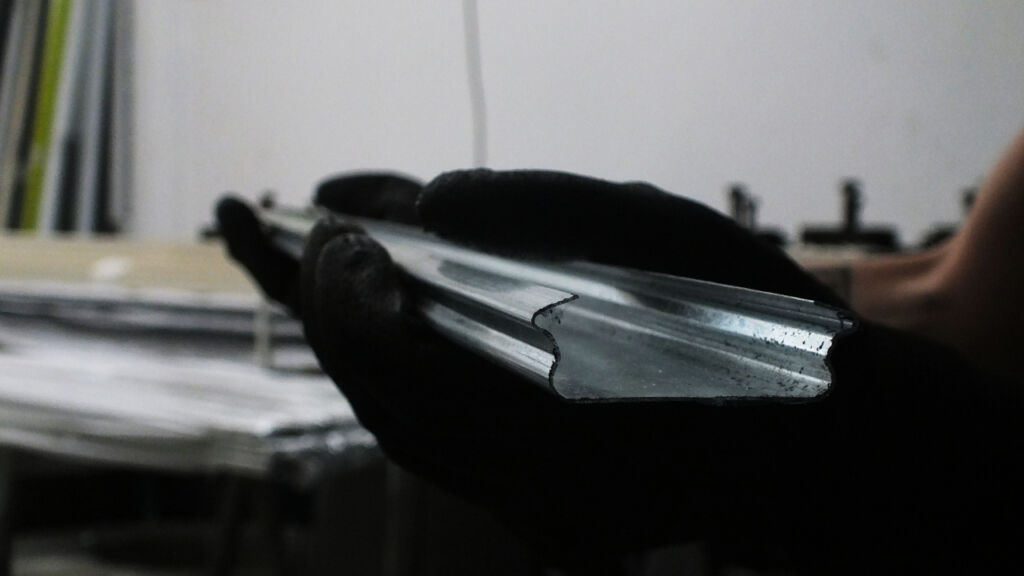

Custom Metal Profiles

As Jalsan Metal, we are producing custom metal profiles for industrial applications. These profiles may be used in a variety of industries, such as construction, manufacturing, or transportation. Metal profiles can be made from a variety of metals, such as steel, aluminum, or copper, and can be shaped to fit specific design requirements.

How Do We Produce Custom Profiles?

Custom metal profiles can be made through a process called extrusion. Extrusion involves forcing a metal billet, or a cylindrical piece of metal, through a die to create a specific shape. The die is typically made from hardened steel and has a specific profile that corresponds to the desired shape of the final product. The metal billet is heated to a specific temperature, which makes it easier to extrude, and is then pushed through the die using a hydraulic or mechanical press.

Extrusion is a versatile process that can be used to create a wide range of shapes and sizes. The final product can be cut to length and finished with secondary operations such as machining, drilling, or bending, depending on the customer’s specific requirements.

It’s important to work with an experienced metal fabricator who can guide you through the design and manufacturing process, and ensure that the final product meets your requirements and specifications.

The Process of Custom Profile Production

To make custom metal profiles, you will need a few key things:

Design: You will need a design for the custom profile that you want to create. This can be created using computer-aided design (CAD) software or by working with an experienced metal fabricator who can help you with the design process.

Raw materials: We collect the raw materials for your custom profile. This will typically be a metal billet, which is a cylindrical piece of metal that will be extruded to create the profile shape.

Extrusion equipment: We use extrusion equipment, which typically consists of a hydraulic or mechanical press, and a die. The die will be custom-made to the specific shape and size of the profile that we want to create.

Heat treatment equipment: We may need heat treatment equipment, depending on the type of metal that we are working with. Heat treatment can help to improve the strength and durability of the final product.

Secondary operations equipment: We may need secondary operations equipment, such as machining, drilling, or bending equipment, to finish the final product according to our specific requirements.

Skilled workers: We have skilled workers who are experienced in metal fabrication and can operate the equipment and perform the necessary operations to create your custom profile.

Remember, we see challenging projects as invitations to success.

Dimensions of Custom Profiles

There is no specific dimension that is suggested for custom metal profiles since the size and shape of a custom profile will depend on the specific application and design requirements. However, there are some factors that may influence the optimal dimensions of a custom profile.

For example, the dimensions of a custom profile may be influenced by factors such as the strength and durability requirements of the application, the weight and cost of the metal being used, and the manufacturing process used to create the profile.

When designing custom profiles, it’s important to consider the application and the specific performance requirements, such as load-bearing capacity, corrosion resistance, or thermal conductivity. The metal fabricator can help you determine the optimal dimensions for your custom profiles based on your specific application and requirements.

How To Provide?

To get custom metal profiles, our visitors typically need to follow a few steps:

Contact a metal fabrication company: The first step is to find a reputable metal fabrication company that specializes in producing custom profiles. You can search online for metal fabrication companies or ask for recommendations from industry peers or suppliers.

Provide design specifications: Once you have identified a metal fabrication company, you will need to provide them with your design specifications. This may include detailed drawings or CAD files of the custom profile that you want to create, as well as any specific performance requirements.

Get a quote: The metal fabrication company will provide you with a quote for producing the custom profiles based on your design specifications. The quote may include details such as the cost of raw materials, labor, and any additional services or operations required to produce the final product.

Review and approve the quote: You will need to review the quote provided by the metal fabrication company and approve it before production can begin.

Production: Once you have approved the quote and provided any necessary materials or information, the metal fabrication company will begin production of the custom profiles. This will typically involve extruding the metal billet through a custom die to create the desired profile shape.

Finishing and delivery: After the custom profiles have been extruded, they may need to undergo secondary operations such as machining, drilling, or bending to finish them according to your specifications. The metal fabrication company will then package and deliver the finished custom profiles to your location.

It’s important to work with an experienced metal fabrication company that can guide you through the design and manufacturing process and ensure that your custom profiles meet your requirements and specifications.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco.